7 Places Where Cold Drawn Steel is Used

Cold drawn steel is an interesting product. There are three main types of steel processing. Hot rolled steel is exactly what it sounds like – the metal is sent through a series of rollers that shape it while it’s still hot. The same is true of cold rolled steel, the only difference being that the steel is cold as it goes through the shaping process.

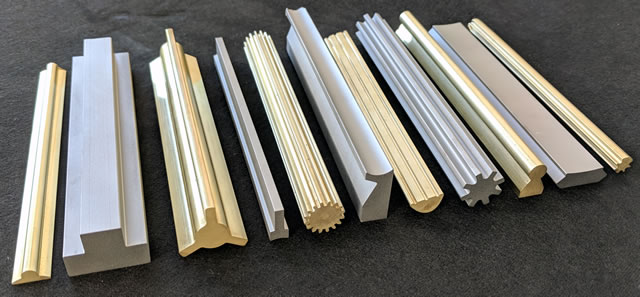

The third main type is cold drawn steel. This type of steel is cooled to room temperature and then it’s sent through a series of mechanisms that pull the steel into thin strips of metal. This drawing process is where this type of steel gets its name. Cold drawn steel can be used to make a number of different things, including the ones listed here.

1) Wheel Spokes

Wheel spokes are one of the most interesting uses of cold drawn steel. These spokes, such as the ones that you see on bicycles, are made from steel that is processed at room temperature and drawn into very thin pieces of metal. This steel is very strong and has a good finish on it, which is why it makes such attractive wheel spokes.

2) Paper Clips

Just about everyone has used or at least seen a paperclip at one point in time. These thin metal objects are made from cold drawn steel. In some cases, the steel is coated with a polymer, allowing the manufacturer to produce paper clips in a wide variety of colors. In others, the paper clips are allowed to remain their traditional metal hue. Either way, they are one of the more unique uses of cold drawn steel. You just wouldn’t think to look in the office supply store for small steel products.

3) Piping

Piping is a common usage of cold drawn steel. These pipes are not the type that you see in a home plumbing system. Instead, they are used in industrial settings. (For the record, home plumbing pipes are made from very thick plastic these days.) Metal pipes come in a variety of different sizes, thicknesses, and weights, all depending on the function and the liquid or thin solids that will sent through them. Many cold drawn steel pipe manufacturers can create these pipes in a custom manner to meet your needs.

4) Metal Bars

Next, there are metal bars. Although the cold drawn steel process makes many think that the only things that can be made from it are round, this is far from the truth. In fact, the drawing process can create corners and edges, meaning that you will end up with metal bars of various types.

These bars can be used for just about anything, ranging from the types that see on the sides of dog kennels and cages to the ones that provide security for windows. It all depends on the overall size and thickness of the bars. Plus, as with the pipes, you’ll be able to order the ones that you need from the manufacturer.

5) Wire

Wire seems like an obvious cold drawn steel product, but it does need to be mentioned here. Like metal bars, wire has plenty of uses, and it comes in a number of different thicknesses. You’ll find metal wire being used for jewelry, for coils in vaping devices, and even in electronic products.

Metal wire forms the foundation for power cords, as well as the electrical cords that you see in the walls of your home. You’d be surprised at the many places where you’ll find this cold drawn steel product.

6) Grating

Have you ever walked over a metal grate and wondered what type of material it’s made from? In most cases, the main parts of that grates (not the edge – the centers) are made from cold drawn steel. This type of steel is incredibly sturdy, making it safe to walk and drive on.

Those grates can hold quite a bit of weight! The outer edges of the grates, the frame, if you will, tend to be made from steel as well, although it’s usually an entirely different type of steel – one that can be formed to fit into the space provided.

7) Miscellaneous Metal Pieces

On top of the six interesting uses for cold drawn steel, there’s a final category simply called “miscellaneous metal pieces.” These pieces of steel consist of things like fastenings, bindings, corner edgings, and more. Basically, they are things that you’ll see in a hardware store.

The fittings and other small metal pieces, all of which serve a crucial purpose when you’re hanging up pictures of even putting things together, are all made using this steel process. They need to be strong enough to stand up to the stresses that are put on them, and if they are made in this way, they certainly are.